Lub semiconductor kev lag luam xav tsis muaj qhov tsis zoo ua kom zoo thiab ua tau zoo, thiab pob zeb diamond sib tsoo tau tshwm sim raws li cov hlua khi no. Paub txog lawv lub hardness, ruaj, thiab txiav kev sib tsoo, ua kom zoo rau kev ua kom zoo thiab cov khoom lag luam zoo nkauj ua haujlwm.

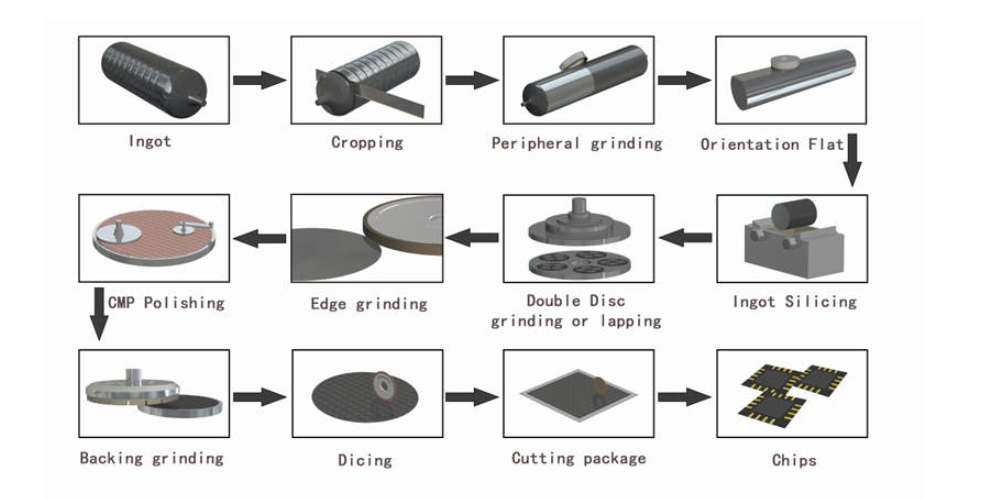

Chaw tsim khoom rau silicon semiconductor

Silicon Ingicon Ingropt (Electroplated bandsaw) ⇒ sib tsoo (pob zeb sib tsoo) ⇒ pawm-⇒ polishing wafing ⇒ ⇒ ⇒ ⇒⇒⇒ sib tsoo (vitrified / cob cov log) ⇒ dicing (dicing tuaj) ⇒ Chips ⇒ mloy molding ⇒ my fling

Cov Ntawv Thov nyob rau hauv kev raug

Wafer Rov Sib Sib Tsoo

Pob zeb diamond sib tsoo cov log muaj ntau ntau rau cov silicon wafers rau qhov yuav tsum thickness, kom muaj qhov chaw du thiab tiaj thaum tswj cov qauv txheej txheem kev ntseeg.

Ntug Sib Tsoo

Txhawm rau kom paub meej txog kev pheej hmoo thiab txo qhov kev pheej hmoo ntawm kev tawg thaum ua haujlwm ntxiv, lub log lub pob zeb diamond tau ua haujlwm rau ntug kev zoo nkauj thiab smoothing ntawm wafers.

Polishing thiab phiaj xwm

High-precision pob zeb sib tsoo cov log yog qhov tseem ceeb hauv kev ua tiav cov khoom siv wafer, kom lawv tau raws li cov hlua khi rau hluav taws xob.

DICING THIAB TEJ

Pob zeb diamond log ua kom huv thiab ua raws li kev txiav wafers rau hauv ib leeg chips, txo cov khoom siv wastage thiab ua kom muaj cov khoom siv zoo.

Ntawm Zhengzhou Rewizhou Rockuan tuam tuam tsev Co., Ltd., peb tshwj xeeb hauv kev muab cov kev xav tau ntawm cov kev lag luam semiconductor. Peb cov khoom lag luam tsim rau qhov tseeb, ua haujlwm, thiab kav ntev, kom ua tau zoo tshaj plaws hauv txhua daim ntawv thov.

Lub Sijhawm Post: Dec-20-2024